Embracing HSE change with a fluidcare solution that gives longevity to production and security to operators

Modern day metalworking fluids require stringent fluidcare to maximise performance, reduce downtime, manage health and safety risk and reduce waste disposal costs. As soluble cutting fluids have evolved in recent years, the importance of high level technical support has become a large part of a manufacturers annual budget.

Varcare Fluid Logic was launched in 2019 to compliment the high performance Varcool soluble cutting fluid range which has the ability to service every application needed in the manufacturing industry. Combining the Varcare Fluid Logic and the Varcool range of metalworking fluids gives the manufacturers confidence that they have the right product and the best service to allow their business to operate efficiently and cost effectively.

Varcare Fluid Logic

Our team of UK Technical Service Engineers are trained to the highest level of Microbiology.

Varcare Fluid Logic service level agreements are maintained by our UK team, who not only complete the contractual service but are specialises in working with production departments to implement site improvements which continue to be ahead of the HSE requirements which continue to challenge all manufactures.

Varcare Service Level Agreement

Tier One

A program designed to take full control of a manufacturing facility fluidcare. This package will satisfy all HSE requirements and provide on site improvements working closely with our Technical Service Engineers.

- Fluid Culture Slide Reports

- Fluid Dilution & pH Reports

- Varcare Fluid Logic Document Board

- On-site Training

- Sump Side Additions

- Varcare Red/Green Light Report

- Fluid Handling Improvements

- Site Cleanouts (extra fee required)

Tier Two

Most suited to subcontractors with limited resource for fluidcare, this service will show improvements in your health and safety towards Metalworks Fluids.

- Fluid Dilution & pH Reports

- On-site Training

- Sump Side Additions

- Varcare Red/Green Light Report

Tier Three

Whether it's a quarterly visit required, a technical issue or simply looking for guidance with your in-house checks, this service is for your production facility.

- Fluid Dilution & pH Reports

- Varcare Red/Green Light Report

Additional Information

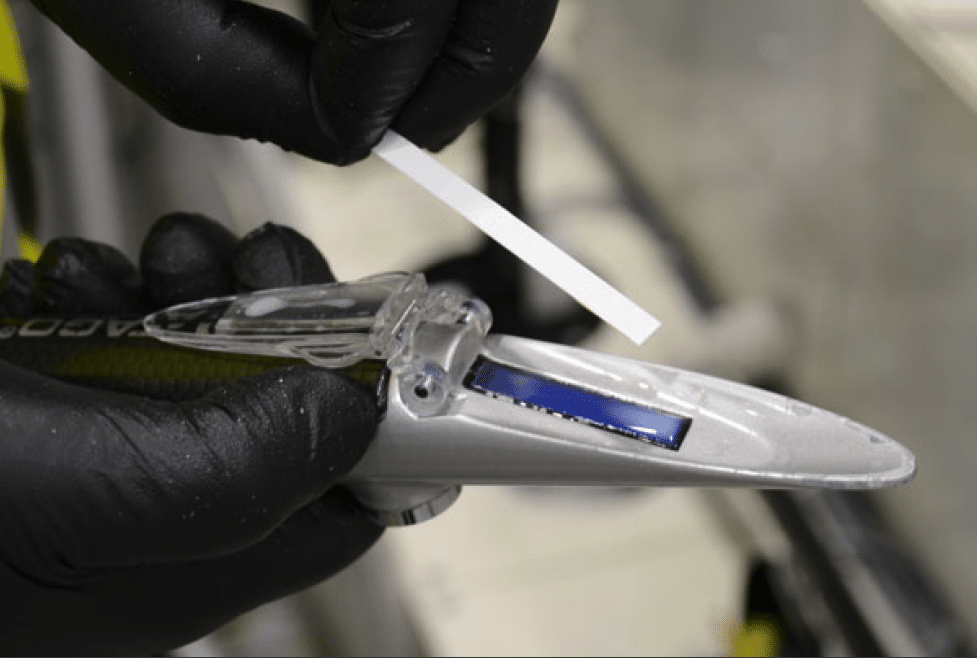

Dipslides

A dipslide consists of a plastic carrier coated with a sterile culture medium, which is dipped into the liquid to be tested. It is then incubated to allow microbial growth and the resulting colonies are estimated by reference to a chart to indicate the level of bacterial contamination. Results are expressed in terms of colony-forming unites per millilitre (CFU/ml) of fluid.

- <104 CFU/ml Good Control. Bacteria are being maintained at low levels. Regular checks and actions to maintain the fluid quality should continue.

- >104 to <106 CFU/ml Reasonable Control. Review and take action to check the quality of the metalworking fluid and adjust fluid parameters to those recommended by the supplier. If bacterial growth continues despite these adjustments, add biocide at the dose recommended by your supplier.

- >106 CFU/ml Poor Control. Immediate action should be taken in line with the risk assessment. Normally training and cleaning should take place.

Dilution

To guarantee an optimum machining process of your materials, it is mandatory to have the right coolant concentration of your water-soluble coolant. Depending on the coolant concentration, machine process and material, a different concentration may be required. The consequences of the concentration being too low or too high (wrong mixing ratio) can be as follows:

High Concentration

- Foam

- Smoke

- Oily residue & deposits

- Skin irritation

Low Concentration

- Corrosion on workpiece and machine

- Decreased tool life

- Fungus & bacteria

- Reduced sump life

PH

pH is measured on a scale of 0-14 and most metalworking fluids are designed to be be alkaline (i.e. pH 8 - 10) in use. However, contamination from other chemicals and more critically high microbiological growth (bacteria, yeast and fungi) can produce acids which lower the pH and cause instability and a health concern. pH Strips are designed for the engineer/operator to monitor the pH level of the fluid quickly and easily.