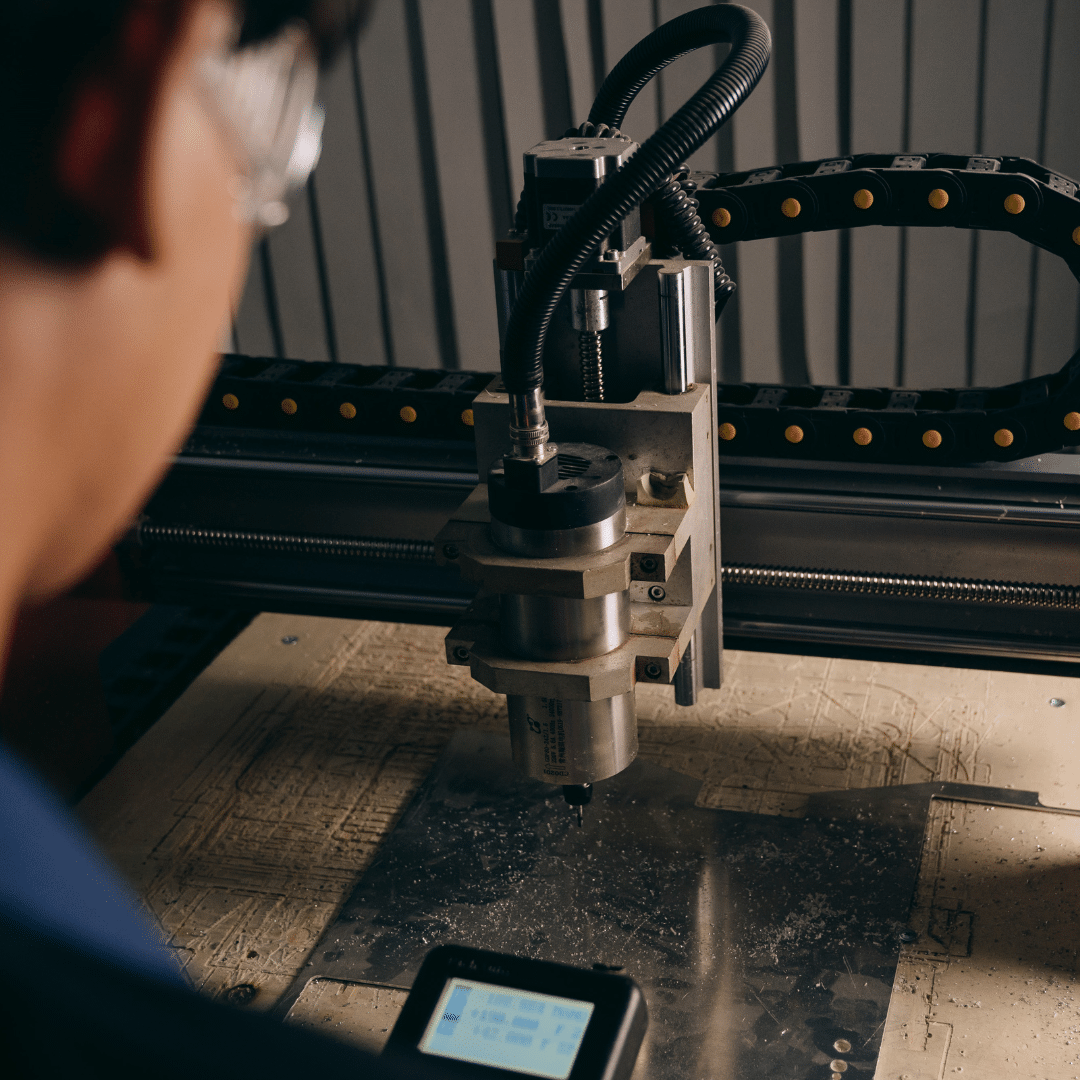

CNC Machine Servicing In The UK

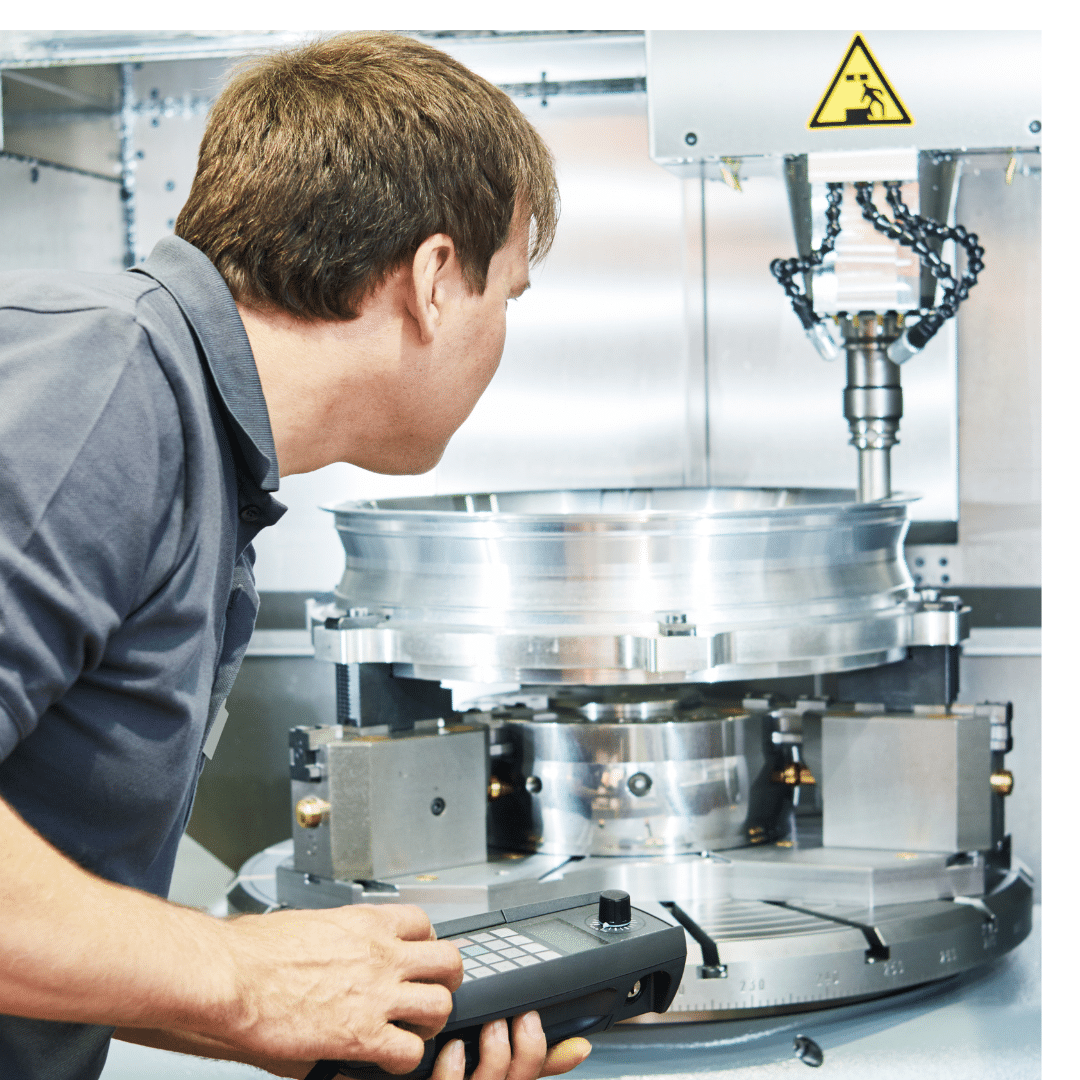

Midland Oil Group has joined forces with King Machine Tool Services to offer a complete, all-in-one solution for precision machine tool owners across the UK.

We combine the expertise of CNC machine repairs with our own, in-house metalworking lubricants to offer comprehensive CNC machine maintenance services.

Together, we offer a fully integrated service that includes CNC machine repair services, machine tool maintenance, spindle repairs, coolant tank cleaning, and bespoke MWF fluidcare management. We regularly service machines in industries where performance and minimal downtime are critical. This includes:

- The motorsport industry

- Aerospace

- Automotive

- Manufacturing

- And precision engineering

We can formulate bespoke metalworking coolants tailored to the needs of your equipment thanks to our in-house R&D and blending services. Our combined expertise in CNC machine maintenance and fluid management allows you to minimise downtime to your operations. Our solutions ensure high levels of machine precision and accuracy, whilst also helping to extend the lifespan of your equipment.

Get in touch today for bespoke CNC machining servicing and repairs, and take advantage of the combined expertise of two leading CNC machine maintenance companies.

CNC Machine Maintenance Companies UK

As demand for high-accuracy component production continues to grow, the need for reliable servicing grows with it. This includes both preventative CNC machine maintenance and CNC machine repairs. This is where Midland Oil Group and King Machine Tool Services step in.

As two leading CNC machine maintenance companies in the UK, we combine decades of expertise in both CNC machine repairs and the formulation of metalworking lubricants to deliver fully-integrated machine tool servicing.

Our integrated service is both proactive in safeguarding the longevity of your precision machinery, as well as being highly performance-driven; ensuring your equipment runs at peak operational capacity.

Our metalworking fluids are trusted across a wide spectrum of industries who rely on our lubricants and coolants to keep their CNC machines operating at peak efficiency.

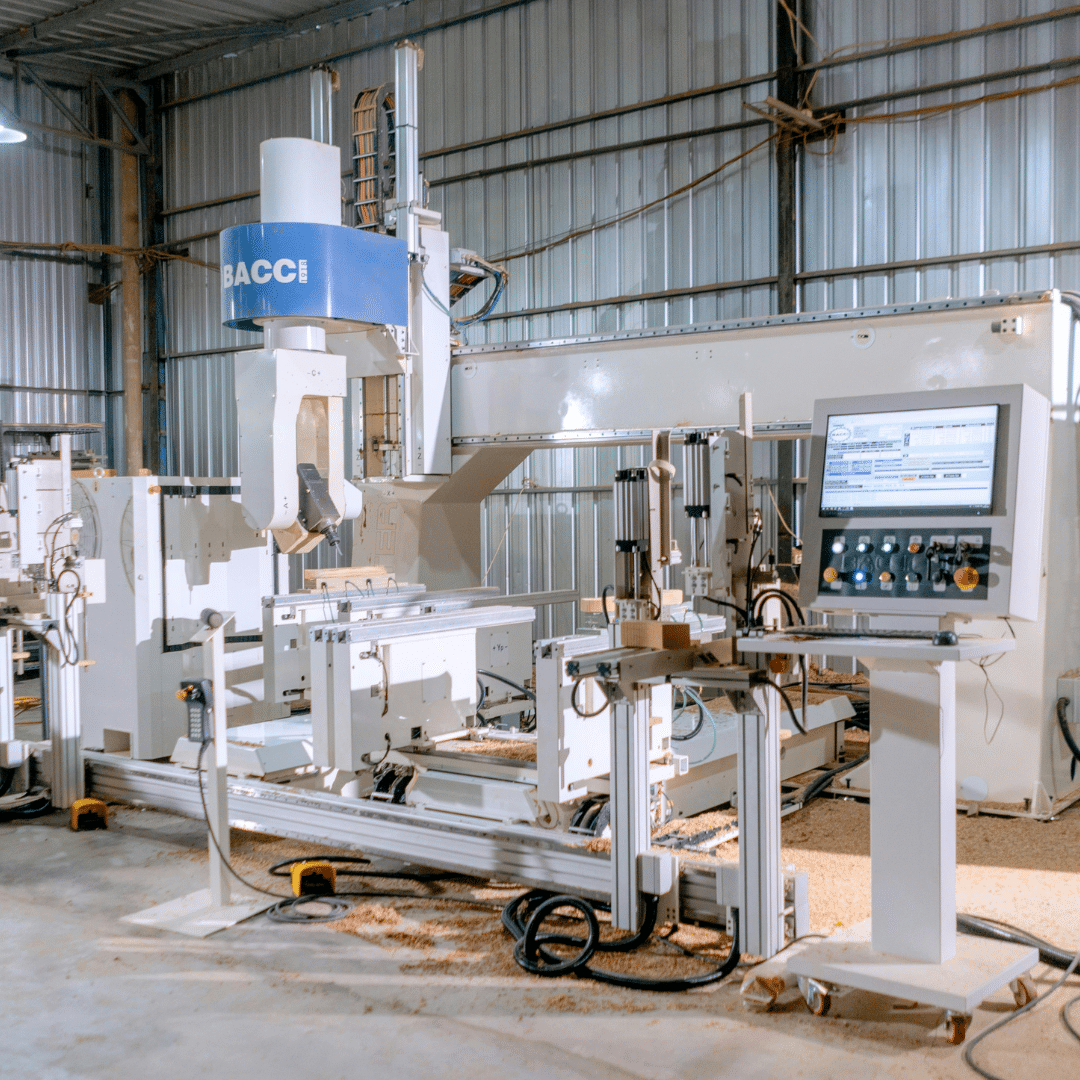

CNC Machine Repair Services

King Machine Tool Services and Midland Oil Group are two leading CNC machine maintenance companies based in the West Midlands. Together, our teams support local manufacturers in aerospace, automotive, medical, precision engineering sectors, and many others. The full list of services on offer includes:

- Emergency CNC machine repair services

- Scheduled preventative maintenance

- Spindle repairs, rebuilds and reinstallation

- Ball screw repairs and backlash correction

- Machine relocation and alignment

- Renishaw ballbar performance testing

- AirBench coolant mist extraction installations

We focus on delivering a fast and highly reliable service for our clients. We help to minimise down-time to your operations, whilst maintaining high levels of productivity.

Our solutions leverage preventative machine-care methods to safeguard your equipment from over-heating or breaking down. They also will also help to prevent your equipment from showing signs of wear or fatigue over-time.

This helps to prevent costly breakdowns and operational disruptions, saving our clients thousands in the long-run. We are also just as capable of carrying out emergency repairs and part replacements if need be.

Our integrated CNC Machine Servicing Solution:

Metal CNC Machine Maintenance Companies UK

Preventative maintenance is the foundation of any effective machine tool operation. By working proactively, our team helps businesses across the UK avoid major disruptions to their operations.

Our maintenance programmes are designed to catch and resolve issues before they turn into potentially expensive breakdowns. Here's the key preventative services we offer:

- Regular inspection of machine wear points

- Lubrication and fluid level checks

- Component alignment and calibration

- Coolant condition and tank hygiene analysis

- Safety feature inspections

With King Machine Tool Services managing the machinery, and Midland Oil Group supplying the necessary fluidcare, our clients benefit from a comprehensive, single-source solution. This keeps their operations running smoothly, maximising productivity and saving them thousands in potential breakdown costs.

This makes our all-in-one service a highly convenient and cost-effective option, saving you time, money and the hassle of engaging with multiple contractors.

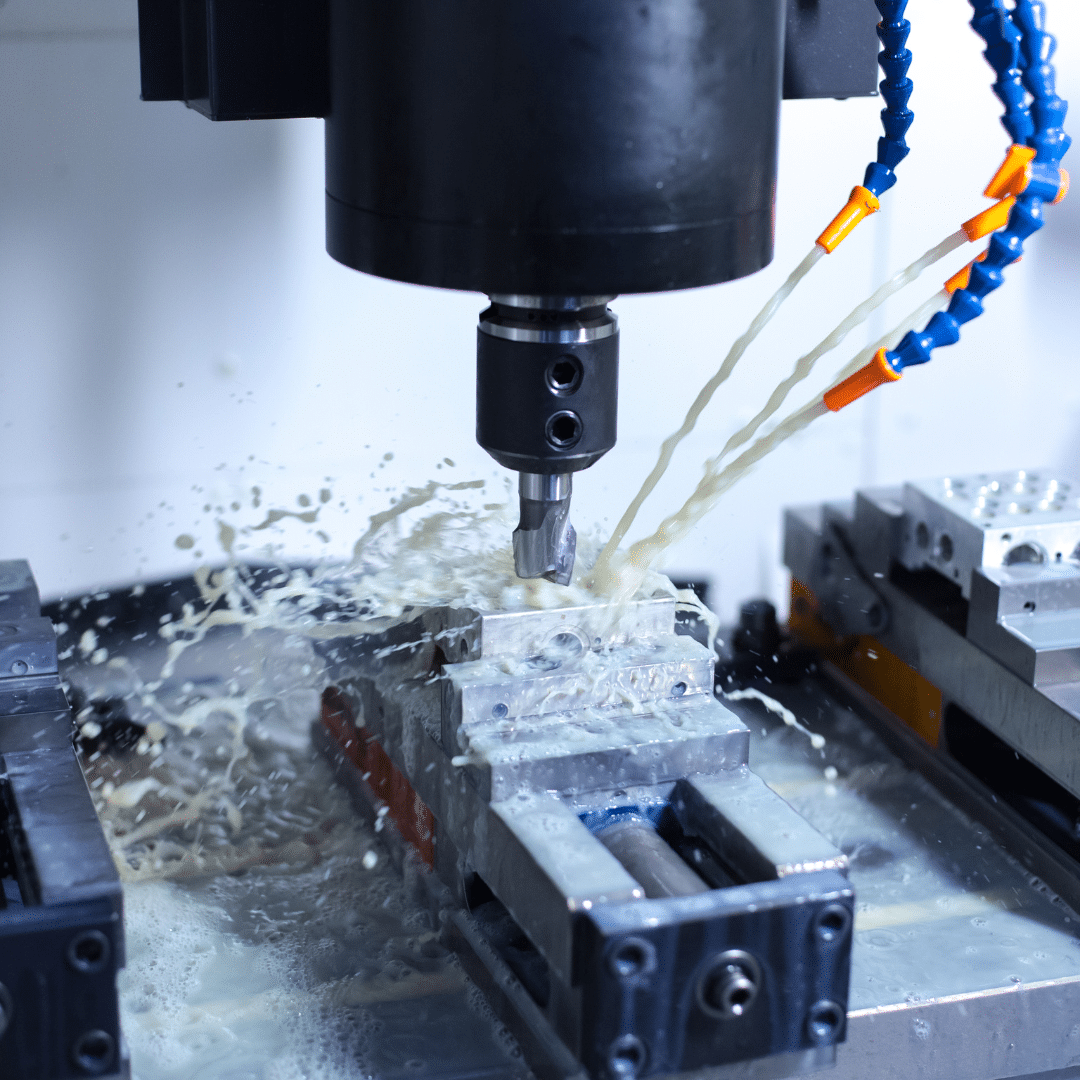

Metalworking Coolants & Lubrication for CNC Machines

As manufacturers push for higher speeds and tighter tolerances, metalworking fluids play a vital role in machine health, as well as production quality. Midland Oil Group offers a full range of metalworking lubricants through our Varol Lubricants line. This is supported by our specialist Varcare Fluid Logic service programme.

Our lubricants and coolants are engineered to extend the lifespan of your equipment, preventing your machines from showing signs of wear or fatigue over-time.

Our UK Technical Service Engineers play a key role in supporting your operations. That's because we don’t just supply fluids, we actively manage their entire lifecycle. From product selection and monitoring right through to waste disposal and recycling, we handle everything all under one roof.

Our in-depth technical knowledge allows us to spot potential issues early. Using advanced diagnostics and monitoring tools, we measure things like fluid condition and microbial activity, which all inform our bespoke service to your operations, guaranteeing reliable results.

Machine Tool Coolant & Lubrication Solutions

Different CNC machines (and the materials they process) need different fluids depending on their specifications and their individual requirements. Using the right lubricant is critical to the precision, as well as the long-term protection of your machinery. Using the wrong lubricants can have very harmful consequences for the performance of your machinery.

Midland Oil Group is proud to offer a comprehensive range of high-quality metalworking fluids that help to cool machinery, optimising their performance and extending tool life. We will be happy to offer you guidance on which lubricant would be best suited to your needs. We can bulk-supply nationwide the following metalworking fluids:

- Soluble cutting fluids

-

Neat cutting oils

-

Forming and vanishing fluids

-

Rust preventatives

-

Quench oils

-

Industrial-grade cleaners

All of our metalworking fluids are specifically formulated to handle the demands of modern manufacturing. They support everything from high-speed cutting operations to corrosion prevention and component finishing. No matter your industry, we will have a lubricant that can enhance the life of your tools, improve your surface-finishing, and reduce cycle times.

Why is Regular CNC Machine Servicing Important?

CNC Spindle Repair & Maintenance Services UK

Spindles are central to machine tool performance. They are responsible for driving speed, accuracy, as well as cutting precision. When spindle wear goes unchecked, this can lead to component failures and costly downtime.

In partnership with King Machine Tool Services, we offer a complete spindle servicing solution. This includes:

-

Full spindle disassembly & bearing replacement

-

Precision balancing & reinstallation

-

On-site testing & performance verification

At the same time, we will assess your fluid delivery systems to ensure the right levels of lubrication is reaching the spindle and cutting zones. This is because poor lubrication is a common cause of spindle wear. So addressing both mechanical and fluid systems together prevents issues before they escalate.

This dual-focus approach that we take ultimately improves the accuracy of your machines. whilst also extending spindle life, and reducing unexpected interruptions to your operations.

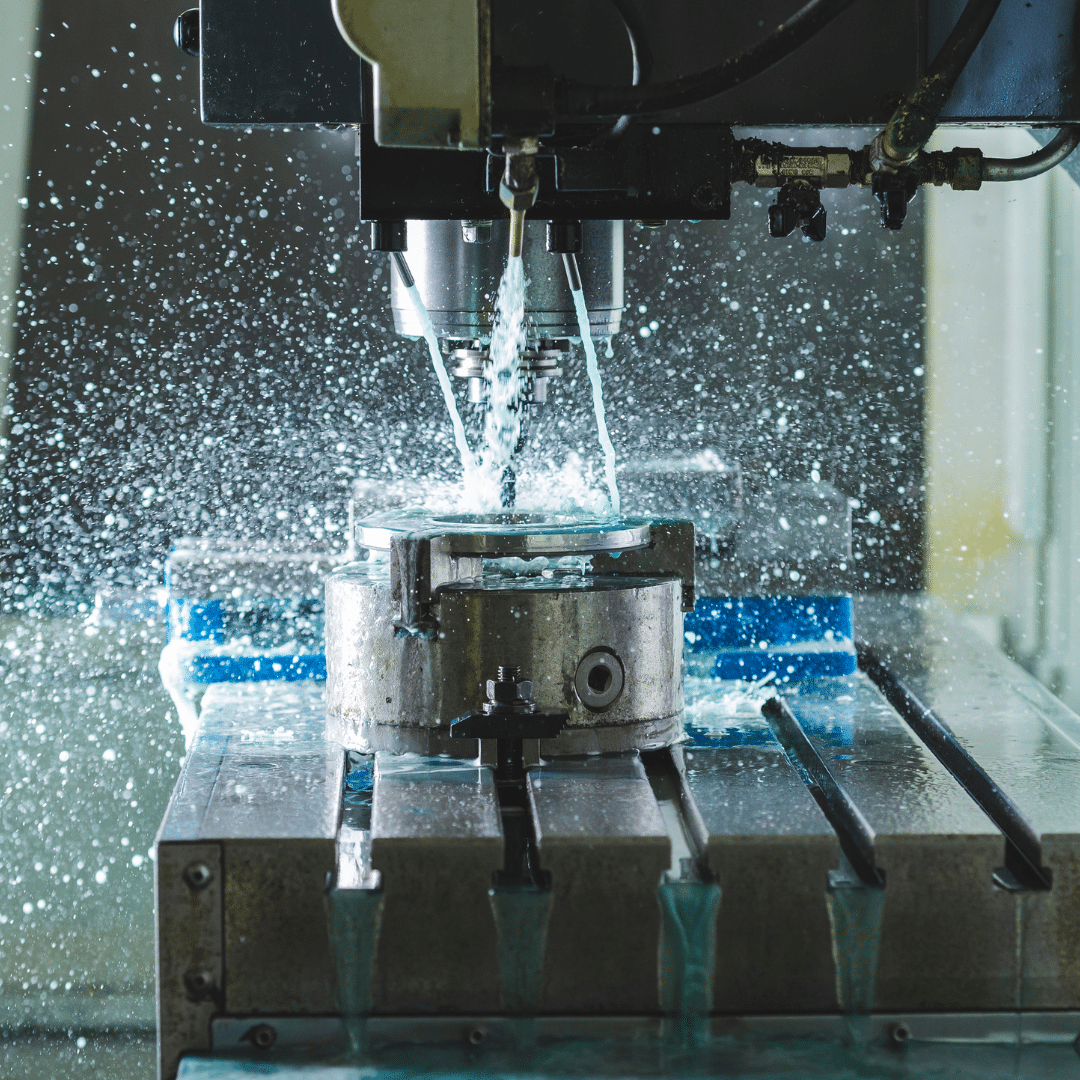

CNC Coolant Tank Cleaning Services UK

Coolant degradation, swarf accumulation, and bacterial contamination may not always warrant much attention. Over time however, these can silently chip away at machine performance and lifespan, leading to decreased output and potential failures.

Together with King Machine Tools Services, Midland Oil Group offers specialist antibacterial CNC coolant tank cleaning services. With years of hands-on experience, we’ve mastered what it takes to do the job properly first time, every time.

Many of our customers attempt tank cleaning themselves, only to find they have to repeat the process due to missed spots or ineffective methods. Our team however applies proven best practices, using the right cleaners and techniques to deliver a comprehensive, long-lasting clean. We set the benchmark for CNC coolant tank maintenance, ensuring your machines continue to operate at peak performance.

Our industry-leading CNC coolant tank cleaning service includes:

-

Full decontamination and deep cleaning of coolant tanks.

-

Removal of sludge, grime, and microbial buildup from internal machine surfaces.

-

Recharging your system with our high-performance Varcool cutting fluids.

Clean systems don't just look and smell nicer, they also run better, making it an important consideration for any business-owner. Proper tank hygiene helps extend the life of your fluids and ensures your setup meets HSE standards. They also reduce corrosion risk, and protects operators from unnecessary exposure to harmful substances.

By making cleanliness a routine, and not just an afterthought, you can boost the efficiency of your systems and safeguard the long-term health of your CNC equipment.

Why Choose Midland Oil Group for CNC Machine Servicing?

Midland Oil Group and King Machine Tool Services bring together industry-leading expertise from two sides: the scientific (metalworking lubricant formulation), and the mechanical (CNC machine repair services and maintenance).

Our integrated approach therefore allows you to achieve the best of both worlds for your business when it comes to the long term servicing and maintenance of your machinery. Leverage our combined expertise, and you'll be gaining access to:

✔️ One supplier, one solution for oil supply, fluidcare, machine repair, and rebuilds

✔️ Regular on-site fluid analysis through our Varcare Fluid Logic programme

✔️ Microbiological monitoring to maintain fluid health and performance

✔️ Expert guidance on compliance and fluid safety standards

✔️ Over 5,000 high-performance Varol Lubricant formulations

✔️ Over 150 years of combined industry experience and technical expertise

✔️ Data-driven recommendations to extend machine life and improve productivity

✔️ UK-wide technical support and lubricant delivery

CNC Machine Repair Services & Maintenance

So if you’re looking for a partner who can handle both the mechanical servicing and fluid health of your machinery, Midland Oil Group are the company to call.

Based in the West Midlands, Midland Oil Group and King Machine Tool Services are two CNC machine maintenance companies that you can depend on for UK-wide servicing. We work with businesses from a diverse range of industries to deliver reliable, cost-effective CNC machine servicing, including CNC machine repairs and routine maintenance.

Get in touch with Midland Oil Group today using our online contact form below. Alternatively, call us on 0121 585 6006, or email us at sales@midlandoil.co.uk. We look forward to working with you to deliver the reliable servicing your precision machinery needs to continue operating at peak efficiency.